PRINTING

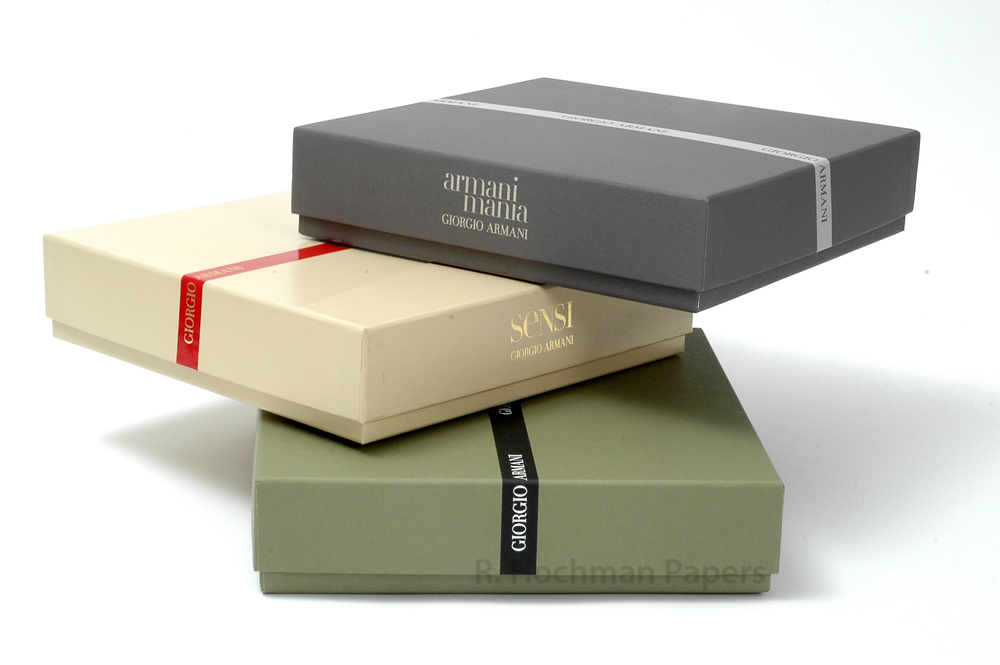

R. Hochman Papers maintains the highest quality standards for printing. We also offer decorative finishing services: die-cutting; embossing; leaf stamping and laminating.

Tell us what you need and email a picture or concept. We’ll work with you to determine the best methods and technologies to realize your packaging vision.

Also known as “Flexo”, is among the most common forms of printing for packaging. Flexo is a high-speed print process that uses fast-drying inks. This method prints well on an array of materials, including paper, plastic films, tissue paper and foils. It’s especially well-suited for printing simple gift wrap and tissue paper.

Gravure is often used for high quality printing, where color consistency is an absolute must. With gravure, an image is first etched on the surface of a metal plate, then the etched area is filled with ink, and the plate is rotated on a cylinder that transfers the image to the paper. R. Hochman Papers has traditionally relied on gravure as the preferred method of printing for its highest quality of standard in printing.

Offset lithography is a widely used printing technique where an image is transferred from a plate to a blanket that comes in direct contact with the paper. Offset inks can be dried both conventionally (air-dried) or with an ultra violet coating.

This is a metal stamping process that requires the use of heat and pressure to imprint paper or other materials. It’s often used to accentuate a logo or design on a package. R. Hochman Papers can also combination hot stamp and emboss your designed image for extra emphasis.